DESIGN AND IMPLEMENTATION OF A novel power scrambler FOR IMPROVING

FUEL EFFICIENCY.

Abstract

To meet the challenges

of constantly rising fuel supplies, a new power scrambler with high efficiency

is designed by increasing the kilometre range. In all kind of bikes, mechanical

energy is produced in the front wheel during roving. In this paper, a technique

is proposed to utilize the mechanical energy by using an alternator for

conversion. Alternator is placed in the front wheel of power scrambler which

converts the mechanical energy into electrical energy. Various power

electronics circuits are intended, to utilize the produced energy for charging

the battery in the power scrambler. This helps in increase the efficiency of

the power scrambler. For instance if 10:1:5 is the kilometre ratio of the

electric bike, with the use of the alternator, the kilometre will be decreased

by the ratio 10:1. But subsequent to its connection to the charging system, the

kilometre is increased by the ratio 10:5. The main objective of this paper is

to increase the usage of the electric bike, since this will reduce the usage of

the extinct fuels.

Keywords:

Power

scrambler (electric bike), BLDC motor, DC-DC boost converter, Lead-acid

battery.

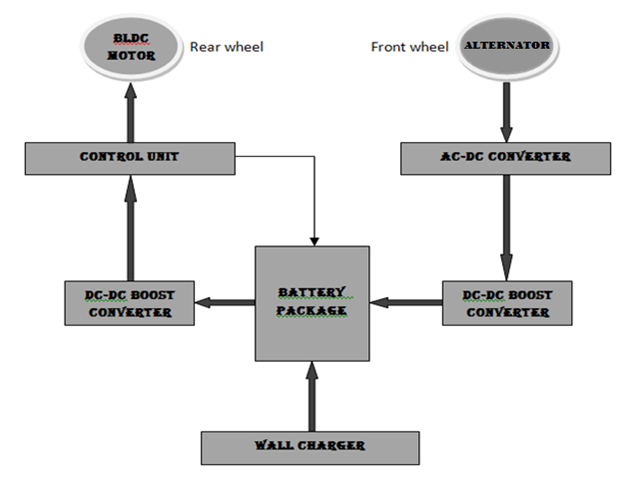

BLOCK

DIAGRAM OF OUR PROJECT

1.Yoshihiro Nakazawa, Chiaki Humagai, Mikio Kato.

“Development of an electric scooter for practical

use” in JSAE

Review 15 (1994) 373-377

2. Chien-Tung Liu, Bing-Ming Lin, Jyh-Sheng Pan.

“Design and development of a zero-emission scooter

for Taiwan” in Journal of Power Sources 59

(1996) 185-187

3. Peter A. Lehman, Charles E. Chamberlin. “Design

and Performance of SERC’s Fuel Cell Powered

Vehicle

Fleet” in Fuel Cell Seminar Abstracts

1998. 714-717

4. H. Yamamura, R. Masaki, O. Koizumi, K. Naoi and

S. Naito,

“Development of powertrain system for Nissan FEV”,

in

Proceedings of the 11th Electric Vehicle Symposium, Florence,

Italy,

1992.

5. J. Marcos, C. M. Peñalver. "An approach to

real behaviour modeling for

traction lead-acid batteries". 32nd Power

Electronics Specialist

Conference

(PESC'2001). Vancouver, Canadá, June 17-22, 2001.

6.Guide for calculating mechanical and electrical

engineering technician guide hatchette technical

editor

7.Bundesamt für Umwelt, Wald und Landschaft (BUWAL),

Sektion Verkehr und

verschiedene Autoren, 2004, “Elektro-Zweiräder, Auswirkungen auf das

Mobilitätsverhalten”.

8.N. H. Kim, O. Yang, M. H. Kim, “BLDC motor control

algorithm for

industrial applications using a general purpose

processor,” Journal of

Power

Electronics, Vol. 7, No. 2, pp. 132-139, Apr. 2007.

9.John G.W. West, “DC, induction, reluctance and PM

motors for electric

vehicles”,

POWER ENGINEERING JOURNAL,

APRIL 1994, pp. 77-88.